Xu Forging Attends the 8th Forum on Automotive Hot Stamping Technology and Process Development

Release time:2024/4/17 8:57:09 Click on the number of times:171

Xu Forging Attends the 8th Forum on Automotive Hot Stamping Technology and Process Development

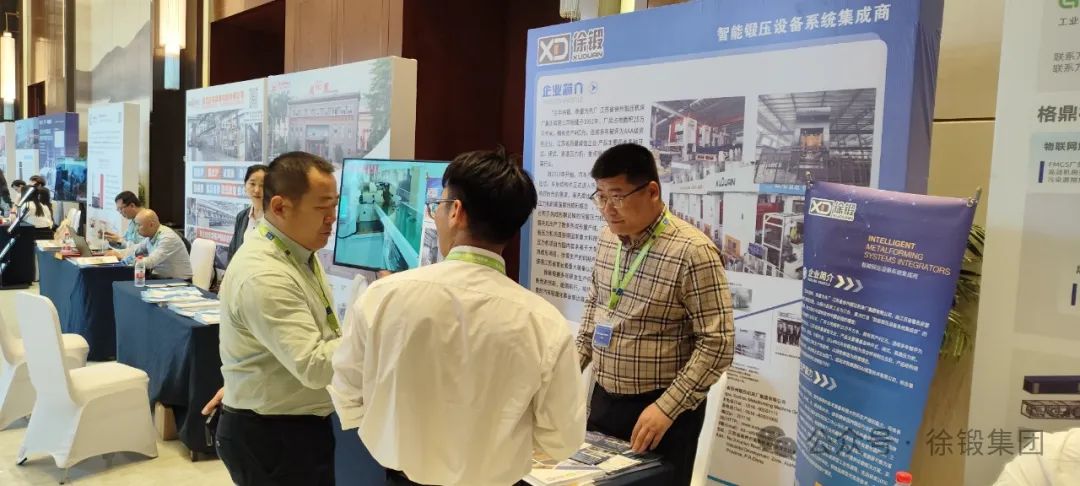

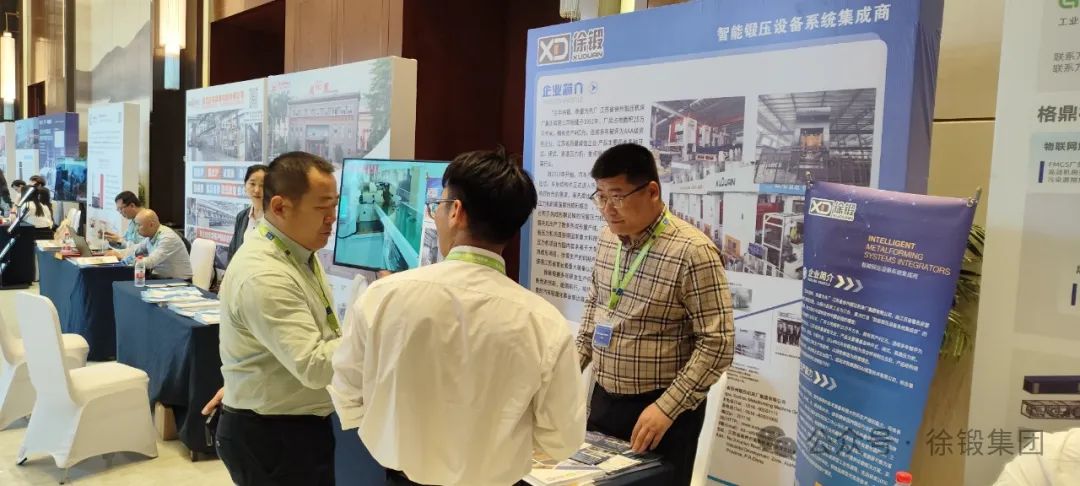

The 8th Automotive Hot Stamping Technology and Process Development Forum, the 4th New Energy Vehicle Die Casting Innovation Technology and Process Development Forum, and the New Energy Vehicle Body Connection Technology Forum were held in Wuhu from April 16th to 17th! More than 600 industry professionals from passenger car manufacturers, automotive parts companies, material companies, intelligent factories and systematic integration companies, press machine companies, industrial furnace companies, and mold companies participated in this exhibition. There were more than 40 host factories, divided into three major venues (main venue, hot stamping venue, and die-casting&connection venue). Chen Jian, General Manager of Xu Forging Group, Li Wei, Vice President, and Fang Xin, Dean of the Research Institute, were invited to participate in the forum and conducted product promotion at the on-site booth.

According to relevant statistics, the production and sales of new energy vehicles in China reached 9.587 million and 9.495 million respectively in 2023, with year-on-year growth of 35.8% and 37.9%. The rapid development of new energy vehicles has increasingly high requirements for endurance, and lightweight technology for automobiles will further enhance the demand for endurance. Hot stamping technology will provide more development space for lightweight new energy vehicles in China. As of now, there are nearly 300 hot stamping production lines in China. Multi component integrated hot stamping technology will be the main development path in the future, and hot stamping technology will move towards integration, high efficiency, low cost, toughness, and oxidation resistance. The application of integrated hot formed door rings and double hole door rings will further promote the lightweight development of automobiles. The optimization design, new materials, new processes, and cost issues of hot stamping parts are also topics of common concern.

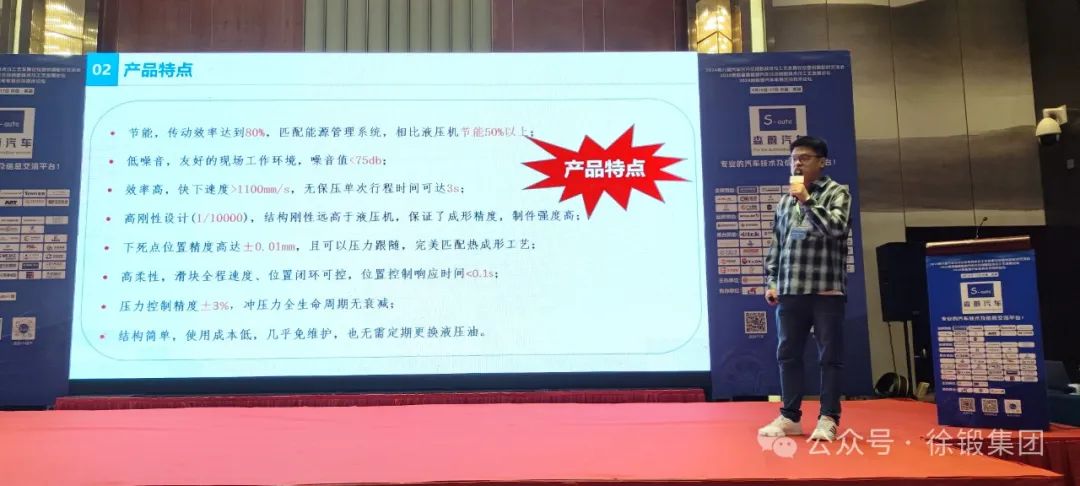

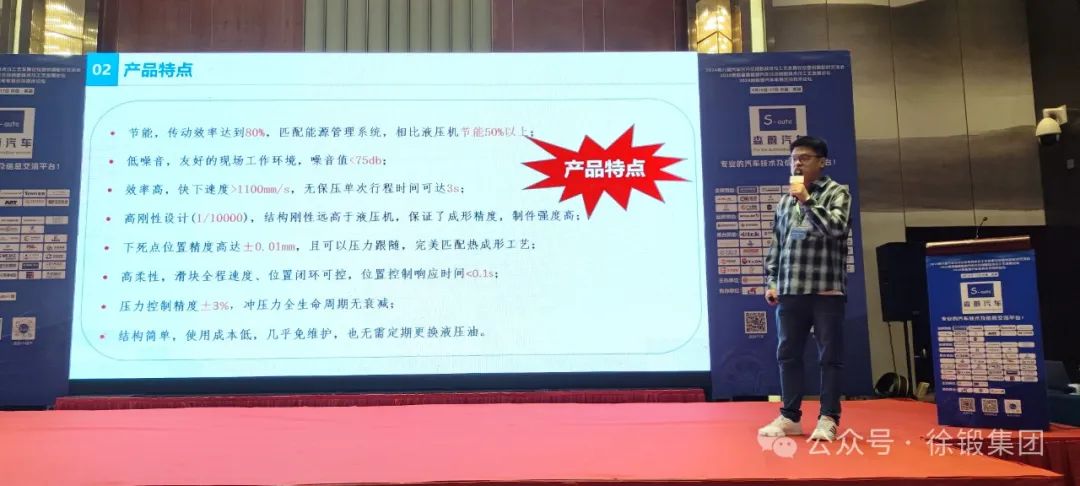

At this forum, Fang Xin, the director of Xu Forging Research Institute, gave a report entitled "Hot stamping forming production line based on fully electric mechanical servo press and roller bottom heating furnace" at the conference. The production line adopts the solution of fully electric mechanical servo press and roller bottom heating furnace, achieving efficient and low consumption green intelligent manufacturing of hot stamping forming. At the same time, President Fang also shared the achievements of Xu Forging Group in the field of hot forming mechanical servo presses in recent years, which received key attention from attending experts and guests.

徐鍛借助本次展會(huì)契機(jī)�,同時(shí)也在展位上與國(guó)內(nèi)汽車熱沖壓成形領(lǐng)域廠商及專家學(xué)者充分交流探討,進(jìn)一步展示了我司在伺服壓力機(jī)熱成形領(lǐng)域的實(shí)際成果����。徐鍛一直致力于打造智能鍛壓設(shè)備系統(tǒng)集成商,未來(lái)徐鍛也會(huì)努力技術(shù)創(chuàng)新引領(lǐng)企業(yè)發(fā)展����,全面實(shí)現(xiàn)制造業(yè)向高質(zhì)量發(fā)展的轉(zhuǎn)變,為中國(guó)制造業(yè)走向世界�,貢獻(xiàn)出一份力量。