The product description

The welded prestressed composite bed ensures the rigidity of the machine. The body of the machine is heat aging stress elimination treatment to ensure that the machine does not deform.

● closed double point structure, suitable for large continuous die stamping, strong anti - bias load.

● low inertia friction clutch - brake, smooth transmission, low noise, long life.

● the slider adopts eight lengthened guide rail, with high accuracy. Guide rail and insert guide long, wear resistance, high precision.

● equipped with electric mode adjustment device, the height of the mode is adjusted by the motor, and the value can be read out from the digital counter.

● equipped with slider balance device, effectively balance the weight of slider and mold.

● the lubrication system adopts the motorized thin oil automatic timing, fixed point and quantitative lubrication system to ensure good lubrication of the press.

● using rotary transformer and mitsubishi PLC+ touch screen control, with feeding signal output and detection interface.

● frequency conversion stepless speed regulation.

● with cumulative counter and single shift counter.

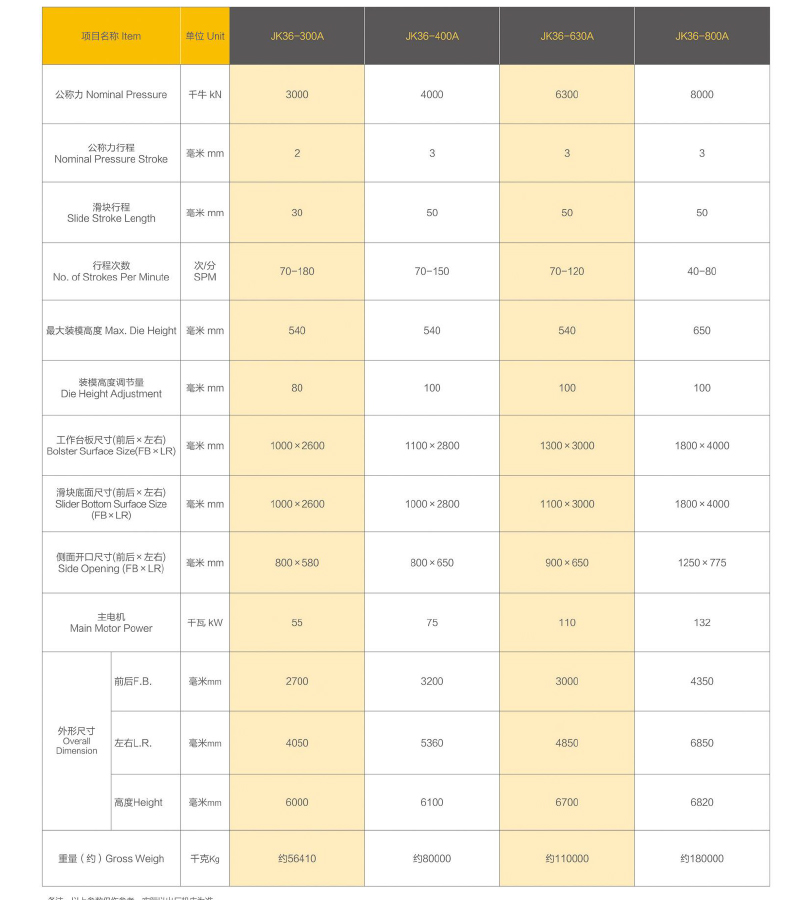

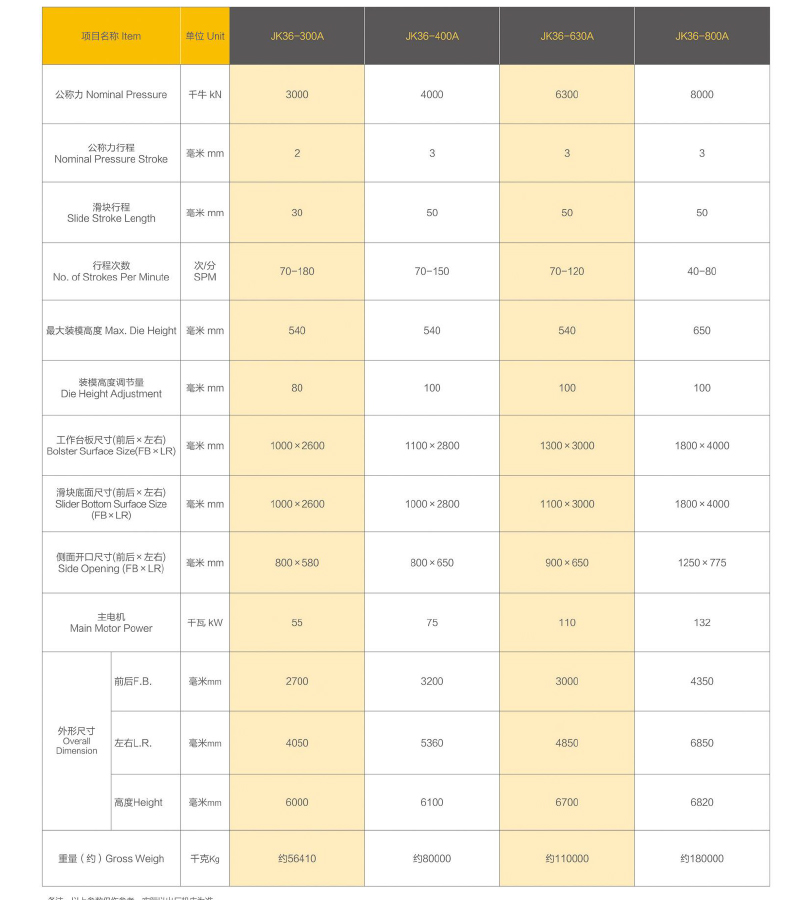

Main technical parameters