The product description

High strength all steel structure fuselage, good rigidity, high precision, 4 or 6 connecting sets, can be used for uncoiling, leveling, feeding mechanism and manipulator to achieve large plate continuous processing production line. With a wide work table, for the convenience of mold change, the table can be moved. It can do blanking, punching, bending, forming, correction, shallow drawing and other cold stamping work for large sheet metal parts. Widely used in automobile, tractor, agricultural machinery, national defense, motor manufacturing, electrical appliances, light industry, textile, machinery, aviation, military and other industrial sectors.

● the base, column, beam and slider adopt welding structure, positioning sleeve positioning, hydraulic pretightening together with tightening bolts:

● the transmission adopts three levels of transmission, one belt transmission, two levels of gear transmission.

● using mechanical and electronic CAM control action specifications;

● connecting rod and slider are connected with guide pillar guide sleeve structure, eight long guide rail guide;

● the clutch brake USES pneumatic low inertia clutch brake;

● slide block adopts hydraulic overload protection device, import pump valve control;

● high mobility adjustment, electronic display;

● thin oil cycle lubrication and thick oil gap lubrication, with high and low oil level detection, timing, fixed point, quantitative lubrication

● PLC double circuit control is adopted for electrical equipment;

● the press is equipped with safety bolts to ensure personal safety;

● can be selected with rigid beating, special vibration isolator, moving table, rapid mold change, adjustable stroke air cushion, automatic mold adjustment

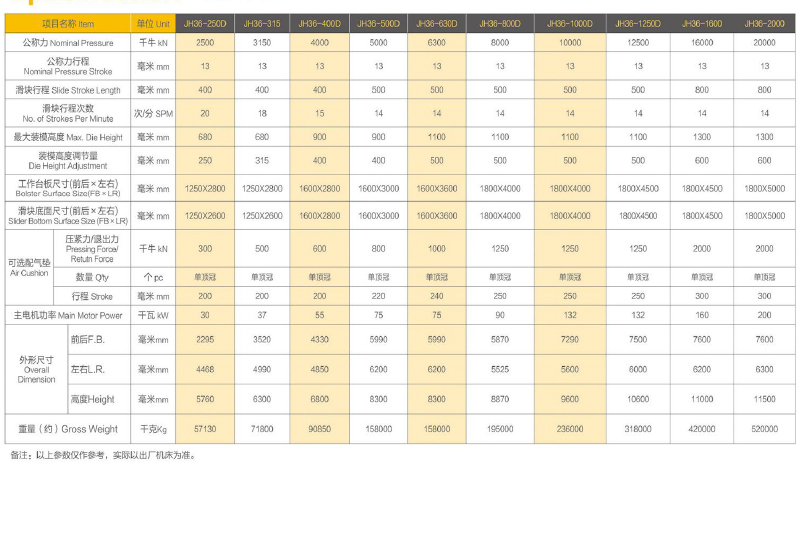

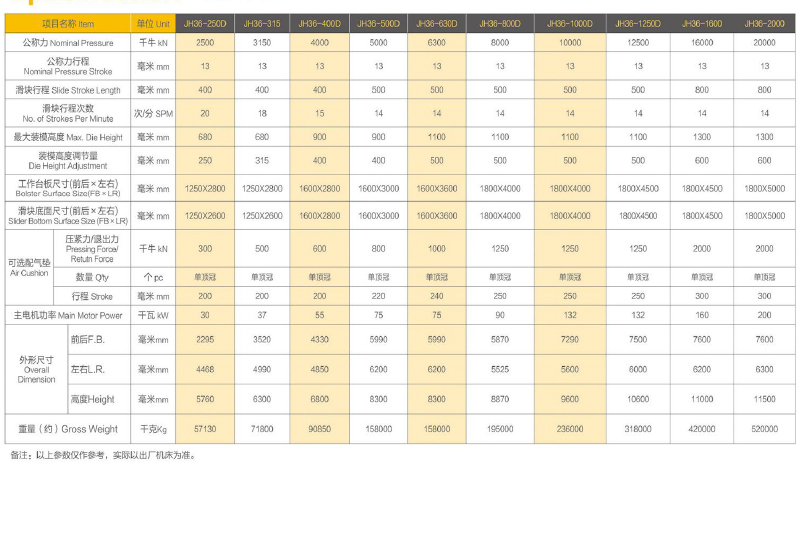

Main technical parameters